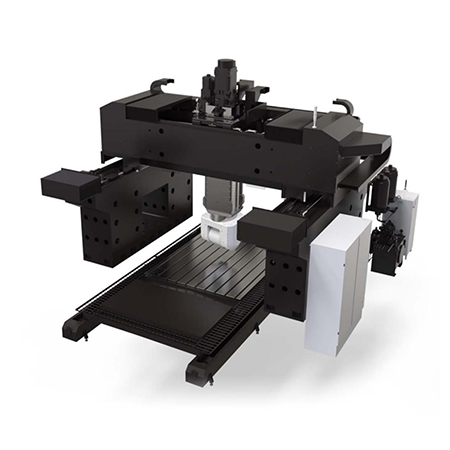

Lima sumbu gantry machining puseur runtuyan PM-GUN

Fitur

Séri produk ieu mangrupikeun pusat mesin gantri gantri lima sumbu anu dikembangkeun sorangan. Ngadopsi struktur balok simetris kotak-di-kotak pikeun nyumponan kabutuhan pamrosésan torsi tinggi, kaku tinggi, sareng alloy titanium efisiensi tinggi, alloy suhu luhur sareng bagian-bagian sanés.

Seri PM-GUN

Struktur crossbeam kotak-di-kotak anu kaku tinggi dilengkepan ku kakuatan tinggi sareng torsi tinggi A / C ganda-ayun sirah, anu gaduh kamampuan motong anu kuat sareng stabilitas presisi.

Crossbeam

Ieu adopts desain struktur crossbeam simetris kotak-di-kotak, badag-bentang konfigurasi opat-lagu, sarta blok slide disimpen di tengah crossbeam nu, ku kituna sakabeh mesin ieu merata stressed, nu greatly ngaronjatkeun kahirupan. étapituduhjeung ingetan akurasi.

A / C sirah ayun ganda

Diimpor-precision tinggi, tinggi-dinamis sirah ayun ganda, dilengkepan-speed tinggi na spindle listrik-torsi tinggi, bisa minuhan sarat processing efisiensi tinggi na motong kuat bagian.

Dual motor drive

Anu panjang-ngarambatdrive adopts rak gear dual-motor struktur anti backlash, nu boga ciri rigidity transmisi kuat, precision tinggi jeung pangropéa gampang.

Majalah alat

Rupa-rupa jenis majalah alat, 24/32/40/60, sadia pikeun éféktif shorten jam machining bantu.

Deteksi posisi loop katutup pinuh

Deteksi posisi sumbu X, Y, sareng Z tina alat mesin ngadopsi presisi anu diimporskala optiks, sarta sumbu A jeung C ngadopsi encoders sudut precision tinggi pikeun ngahontal eupan balik posisi loop-tutup pinuh pikeun ngawujudkeun kontrol loop-tutup pinuh tinamesin, kukituna mastikeun akurasi posisi mesin.

Spésifikasi teknis

| Barang | Unit | RFPM2040GUN | RFPM2060GUN | RFPM2540GUN | RFPM2560GUN |

| rentang ngolah |

|

|

|

|

|

| X / Y / Z perjalanan sumbu | mm | 4000/2200/1000 | 6000/2200/1000 | 4000/2700/1000 | 6000/2700/1000 |

| A / C rentang rotasi sumbu | ° | ± 110/± 360 | ± 110/± 360 | ± 110/± 360 | ± 110/± 360 |

| Gantry lebar éféktif | mm | 3200 | 3200 | 3700 | 3700 |

| Jarak ti irung spindle ka worktable | mm | 100-1100 | 100-1100 | 100-1100 | 100-1100 |

| Méja gawé |

|

|

|

|

|

| Diménsi worktable | mm | 2000 × 4000 | 2000 × 6000 | 2500 × 4000 | 2500 × 6000 |

| Kapasitas bantalan beban worktable | t/m² | 5 | 5 | 5 | 5 |

| spésifikasi T-slot | mm | 28 | 28 | 28 | 28 |

| Eupan drive |

|

|

|

|

|

| Max. laju eupan X / Y / Z | m / mnt | 15/15/15 | 15/15/15 | 15/15/15 | 15/15/15 |

| Max. speed feed A / C | rpm | 60 | 60 | 60 | 60 |

| Laju gancang X/Y/Z | m / mnt | 20/20/20 | 20/20/20 | 20/20/20 | 20/20/20 |

| A/C laju gancang | rpm | 100 | 100 | 100 | 100 |

| Spindle |

|

|

|

|

|

| Métode nyetir |

| Spindle listrik | Spindle listrik | Spindle listrik | Spindle listrik |

| Max. speed spindle | rpm | 7000 | 7000 | 7000 | 7000 |

| kakuatan spindle (S1 / S6-40%) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Torsi spindle (S1 / S6-40%) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majalah alat (opsional) |

|

|

|

|

|

| Kapasitas majalah alat | T | 24 | 24 | 24 | 24 |

| Jenis wadahna alat |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. diaméterna alat | mm | ф125/ф170 | ф125/ф170 | ф125/ф170 | ф125/ф170 |

| Max. panjangna alat | mm | 300 | 300 | 300 | 300 |

| Max. beurat alat | kg | 15 | 15 | 15 | 15 |

| Akurasi |

|

|

|

|

|

| Akurasi posisi X/Y/Z | mm | 0.020/0.012/0.014 | 0,028 / 0,012 / 0,014 | 0.020/0.018/0.014 | 0,028 / 0,018 / 0,014 |

| Pangulangan X/Y/Z | mm | 0,012 / 0,010 / 0,010 | 0,018 / 0,010 / 0,010 | 0,012 / 0,012 / 0,010 | 0,018 / 0,012 / 0,010 |

| Lain |

|

|

|

|

|

| beurat mesin | t | 67 | 75 | 70 | 80 |

| Dimensi mesin (L × W × H) | cm | 900×670×600 | 1100 × 670 × 600 | 900 × 720 × 600 | 1100 × 720 × 600 |

| Barang | Unit | RFPM3040GUN | RFPM3060GUN | RFPM3560GUN | RFPM3580GUN |

| rentang ngolah |

|

|

|

|

|

| X / Y / Z perjalanan sumbu | mm | 4000/3200/1000 | 6000/3200/1000 | 6000/3700/1000 | 8000/3700/1000 |

| A / C rentang rotasi sumbu | ° | ± 110/± 360 | ± 110/± 360 | ± 105/± 360 | ± 105/± 360 |

| Gantry lebar éféktif | mm | 4200 | 4200 | 4700 | 4700 |

| Jarak ti irung spindle ka worktable | mm | 100-1100 | 100-1100 | 100-1100 | 100-1100 |

| Méja gawé |

|

|

|

|

|

| Diménsi worktable | mm | 3000 × 4000 | 3000 × 6000 | 3500 × 6000 | 3500 × 8000 |

| Kapasitas bantalan beban worktable | t/m² | 5 | 5 | 5 | 5 |

| spésifikasi T-slot | mm | 28 | 28 | 28 | 28 |

| Eupan drive |

|

|

|

|

|

| Max. laju eupan X / Y / Z | m / mnt | 15/15/15 | 15/15/15 | 15/15/15 | 15/15/15 |

| Max. speed feed A / C | rpm | 60 | 60 | 60 | 60 |

| Laju gancang X/Y/Z | m / mnt | 20/20/20 | 20/20/20 | 20/20/20 | 20/20/20 |

| A/C laju gancang | rpm | 100 | 100 | 100 | 100 |

| Spindle |

|

|

|

|

|

| Métode nyetir |

| Spindle listrik | Spindle listrik | Spindle listrik | Spindle listrik |

| Max. speed spindle | rpm | 7000 | 7000 | 7000 | 7000 |

| kakuatan spindle (S1 / S6-40%) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Torsi spindle (S1 / S6-40%) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majalah alat (opsional) |

|

|

|

|

|

| Kapasitas majalah alat | T | 24 | 24 | 24 | 24 |

| Jenis wadahna alat |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. diaméterna alat | mm | ф125/ф170 | ф125/ф170 | ф125/ф170 | ф125/ф170 |

| Max. panjangna alat | mm | 300 | 300 | 300 | 300 |

| Max. beurat alat | kg | 15 | 15 | 15 | 15 |

| Akurasi |

|

|

|

|

|

| Akurasi posisi X/Y/Z | mm | 0.020/0.018/0.014 | 0,028 / 0,018 / 0,014 | 0.028/0.024/0.014 | 0.032/0.024/0.014 |

| Pangulangan X/Y/Z | mm | 0,012 / 0,012 / 0,010 | 0,018 / 0,012 / 0,010 | 0.020/0.016/0.010 | 0.020/0.016/0.010 |

| Lain |

|

|

|

|

|

| beurat mesin | t | 75 | 85 | 90 | 105 |

| Dimensi mesin (L × W × H) | cm | 900×770×600 | 1100 × 770 × 600 | 1100 × 820 × 600 | 1300 × 820 × 600 |