Lima sumbu gantry machining puseur runtuyan PM-U

Fitur

runtuyan ieu produk mangrupakeun timer dimekarkeun balok dibereskeun lima sumbu puseur machining gantri kalawan struktur kompak, kinerja alus teuing, speed tinggi, precision tinggi, rigidity tinggi, jsb Ieu cocog pikeun machining bagian dina rupa-rupa industri kayaning aerospace, mesin rékayasa, angkutan rail, molds precision, kakuatan angin, jsb

Seri PM-U

Ieu adopts-speed tinggi na-precision tinggi A / C sirah ayun ganda sarta dilengkepan-daya tinggi na spindle listrik-torsi tinggi, nu mibanda kamampuhan motong kuat.

A / C sirah ayun ganda

Ieu adopts diimpor-precision tinggi, tinggi-dinamis huluna ganda ayun sarta dilengkepan-speed tinggi,-torsi tinggi spindle listrik, minuhan sarat tinggi pikeun precision komponén, kualitas permukaan, sarta efisiensi processing.

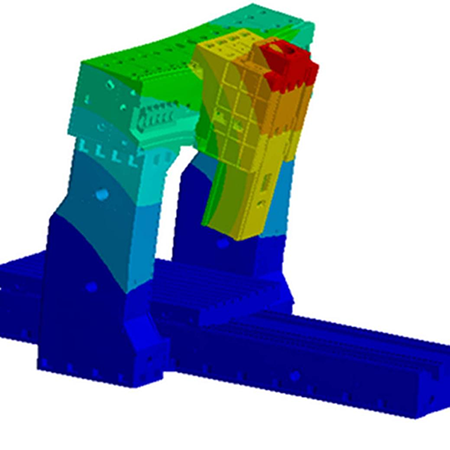

Struktur rigidity tinggi dioptimalkeun desain

Métode desain unsur terhingga digunakeun pikeun ngalaksanakeun analisa statik sareng modal tina sababaraha bagian tinamesinjang meberkeun ngaoptimalkeun struktur produk jeung ngahontal-rigidity tinggi na design struktural lightweight.

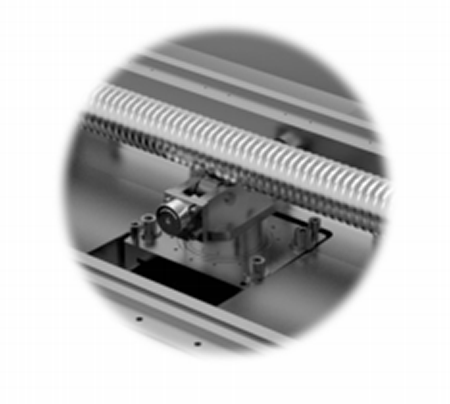

Screw struktur rojongan bantu

Anu panjang-ngarambatscrew kalungguhan ieu dilengkepan rojongan floating, nu bisa éféktif ningkatkeun speed wates tina screw kalungguhan jeung stabilitas rotasi-speed tinggi.

Majalah alat

Rupa-rupa jenis majalah alat, 24/32/40/60, sadia pikeun éféktif shorten jam machining bantu.

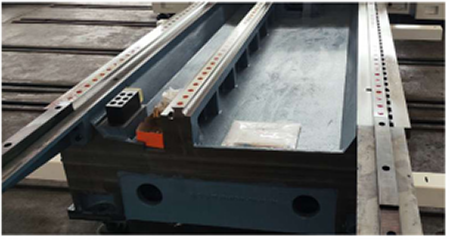

Rojongan rigidity tinggi

Themesinranjang ieu dilengkepan tilu Panungtun badag-ukuran, nu nyadiakeun rigidity rojongan cukup tur ingetan precision.

Desain kaamanan humanized

Desain labyrinth lambar logam di handapeunméja gawényegah chip beusi asup kanamesinranjang. The panyabutan chip terpadu dasarna ngaleungitkeun masalah leakage cai.

Spésifikasi teknis

| Barang | Unit | RFPM3028U | RFPM4028U | RFPM6028U | RFPM4033U |

| rentang ngolah |

|

|

|

|

|

| X / Y / Z perjalanan sumbu | mm | 3200/3200/1000 | 4200/3200/1000 | 6200/3200/1000 | 4200/3700/1000 |

| A / C rentang rotasi sumbu | ° | ± 105/± 360 | ± 105/± 360 | ± 105/± 360 | ± 105/± 360 |

| Gantry lebar éféktif | mm | 2800 | 2800 | 2800 | 3300 |

| Jarak ti irung spindle ka worktable | mm | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Méja gawé |

|

|

|

|

|

| Diménsi worktable | mm | 2000 × 3000 | 2000 × 4000 | 2000 × 6000 | 2500 × 4000 |

| Kapasitas bantalan beban worktable | t | 16 | 20 | 26 | 22 |

| spésifikasi T-slot | mm | 28 | 28 | 28 | 28 |

| Eupan drive |

|

|

|

|

|

| Max. laju eupan X / Y / Z | m / mnt | 12/12/12 | 12/12/12 | 12/12/12 | 10/10/10 |

| Max. speed feed A / C | rpm | 60 | 60 | 60 | 60 |

| Laju gancang X/Y/Z | m / mnt | 20/20/15 | 20/20/15 | 15/20/15 | 15/15/15 |

| A/C laju gancang | rpm | 100 | 100 | 100 | 100 |

| Spindle |

|

|

|

|

|

| Métode nyetir |

| Spindle listrik | Spindle listrik | Spindle listrik | Spindle listrik |

| Max. speed spindle | rpm | 7000 | 7000 | 7000 | 7000 |

| kakuatan spindle (S1/S6) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Torsi Spindle (S1/S6) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majalah alat (opsional) |

|

|

|

|

|

| Kapasitas majalah alat | T | 24 | 24 | 24 | 24 |

| Jenis wadahna alat |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. diaméterna alat | mm | ф110/ф200 | ф110/ф200 | ф110/ф200 | ф110/ф200 |

| Max. panjangna alat | mm | 350 | 350 | 350 | 350 |

| Max. beurat alat | kg | 20 | 20 | 20 | 20 |

| Akurasi |

|

|

|

|

|

| Akurasi posisi X/Y/Z | mm | 0,018 / 0,018 / 0,014 | 0.020/0.018/0.014 | 0,028 / 0,018 / 0,014 | 0.020/0.018/0.014 |

| Pangulangan X/Y/Z | mm | 0,012 / 0,012 / 0,010 | 0,012 / 0,012 / 0,010 | 0,018 / 0,012 / 0,010 | 0,012 / 0,012 / 0,010 |

| Lain |

|

|

|

|

|

| beurat mesin | t | 57 | 63 | 75 | 70 |

| Dimensi mesin (L × W × H) | cm | 910 × 670 × 650 | 1110 × 670 × 650 | 1510 × 670 × 650 | 1110 × 720 × 650 |

| Barang | Unit | RFPM6033U | RFPM8033U | RFPM6038U | RFPM8038U |

| rentang ngolah |

|

|

|

|

|

| X / Y / Z perjalanan sumbu | mm | 6200/3700/1000 | 8500/3700/1000 | 6200/4200/1000 | 8500/4200/1000 |

| A / C rentang rotasi sumbu | ° | ± 105/± 360 | ± 105/± 360 | ± 105/± 360 | ± 105/± 360 |

| Gantry lebar éféktif | mm | 3300 | 3300 | 3800 | 3800 |

| Jarak ti irung spindle ka worktable | mm | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Méja gawé |

|

|

|

|

|

| Diménsi worktable | mm | 2500 × 6000 | 2500 × 8000 | 3000 × 6000 | 3000 × 8000 |

| Kapasitas bantalan beban worktable | t | 30 | 35 | 35 | 40 |

| spésifikasi T-slot | mm | 28 | 28 | 28 | 28 |

| Eupan drive |

|

|

|

|

|

| Max. laju eupan X / Y / Z | m / mnt | 8/10/10 | 8/10/10 | 8/10/10 | 8/10/10 |

| Max. speed feed A / C | rpm | 60 | 60 | 60 | 60 |

| Laju gancang X/Y/Z | m / mnt | 12/15/15 | 10/15/15 | 12/15/15 | 10/15/15 |

| A/C laju gancang | rpm | 100 | 100 | 100 | 100 |

| Spindle |

|

|

|

|

|

| Métode nyetir |

| Spindle listrik | Spindle listrik | Spindle listrik | Spindle listrik |

| Max. speed spindle | rpm | 7000 | 7000 | 7000 | 7000 |

| kakuatan spindle (S1 / S6-40%) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Torsi spindle (S1 / S6-40%) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majalah alat (opsional) |

|

|

|

|

|

| Kapasitas majalah alat | T | 24 | 24 | 24 | 24 |

| Jenis wadahna alat |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. diaméterna alat | mm | ф110/ф200 | ф110/ф200 | ф110/ф200 | ф110/ф200 |

| Max. panjangna alat | mm | 350 | 350 | 350 | 350 |

| Max. beurat alat | kg | 20 | 20 | 20 | 20 |

| Akurasi |

|

|

|

|

|

| Akurasi posisi X/Y/Z | mm | 0,028 / 0,018 / 0,014 | 0.032/0.018/0.014 | 0.028/0.024/0.014 | 0.032/0.024/0.014 |

| Pangulangan X/Y/Z | mm | 0,018 / 0,012 / 0,010 | 0,020/0,012/0,010 | 0,018 / 0,016 / 0,010 | 0.020/0.016/0.010 |

| Lain |

|

|

|

|

|

| beurat mesin | t | 84 | 100 | 94 | 115 |

| Dimensi mesin (L × W × H) | cm | 1550 × 720 × 650 | 2050 × 720 × 650 | 1550 × 800 × 650 | 2050 × 800 × 650 |