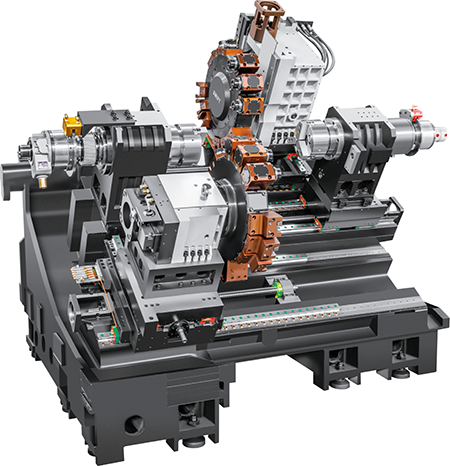

Ngaktipkeun Center TMC Series

Konfigurasi produk

Fitur mesin

Kaku anu luhur, motong beurat, stabilitas anu luhur: ranjang sipit tuang terpadu, ranjang datar, rel condong 45 °, sareng desain iga kandel pikeun ngaminimalkeun distorsi sareng deformasi termal.

High-precision, respon dinamis tinggi:-precision High NSK P4 ballbearings dipaké di hareup jeung pungkur pikeun ngahontal rigidity tinggi na akurasi rotasi highspindle, Unit spindle servo boga precision tinggi na pangropéa merenah.

Efisiensi tinggi: Laju maksimum aci utama nyaéta 6000rpm / mnt, sareng gerakan gancang tiasa ngahontal 24m / mnt. Ngaliwatan konfigurasi sistem CNC generasi anyar Taiwan urang, XC sumbu linkage interpolasi direalisasikeun, sarta fungsi sumbu Y maya direalisasikeun.

Spésifikasi teknis

| Proyék | CNC-460TMC | CNC-520TMC | CNC-680TMC | CNC-860TMC(1000) | CNC-860TMC(1500) | |

| Ranjang Ranjang | Ranjang sareng dasarna didamel tina beusi tuang anu kualitas luhur, sareng ranjangna miring dina 40 °. | Ranjang sareng dasarna didamel tina beusi tuang kualitas luhur. 30 ° ranjang condong | Ranjang sareng dasarna didamel tina beusi tuang kualitas luhur. 45 ranjang condong | |||

| Ngolah Range | Max. diaméterna ayun leuwih ranjang | 540 mm | 600 mm | 600 mm | 780 mm | 780 mm |

| Max. diaméterna ngolah cakram | 360 mm | 320 mm | 400 mm | 650 mm | 650 mm | |

| Max. ngolah diaméter gerbong | 280 mm | 320 mm | 400 mm | 500 mm | 500 mm | |

| Max. ngolah panjang bar | 400 mm | 480 mm | 680 mm | 900 mm | 1400 mm | |

| Max. diaméterna bar | f45 mm | ф51 mm | ф51 mm | ф75 mm | ф75 mm | |

| Travel Feed | Max. perjalanan sumbu X | 220 mm | 220 mm | 230 mm | 350 mm | 350 mm |

| Max. perjalanan Z-sumbu | 470 mm | 520 mm | 750 mm | 1050 mm | 1550 mm | |

| Max. perjalanan sumbu Y | ± 35 mm | ± 45 mm | ± 45 mm | ± 75 mm | ± 75 mm | |

| X / Z / Y sumbu speed gancang | 30m / mnt | 30m / mnt | 30m / mnt | 16m/min | 16m/min | |

| X / Z / Y screw diaméterna / pitch | 32/10 mm | X: 40/10 mm | 40/10 mm | X: 50/08 mm | X: 50/08 mm | |

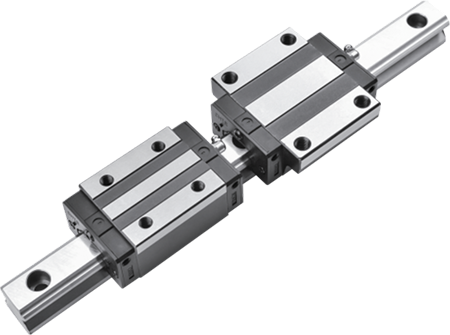

| X / Z lebar pituduh linier | 35 mm | 45 mm | 35 mm | 55 mm | 55 mm | |

| Motor servo sumbu X | β12 (Rem) | β12 (Rem) | β12 (Rem) | β22 (Rem) | β22 (Rem) | |

| Z-sumbu servo motor | β12 | β12 | β12 | β22 | β22 | |

| Y-sumbu servo motor | β8 (Rem) | β12 (Rem) | β12 (Rem) | β22 | β22 | |

| Servo turret motor | 3N.m | 3N.m | 3N.m | 1KW | 1KW | |

| Motor sirah kakuatan | β12 | β12 | β12 | β22 | β22 | |

| Akurasi | Akurasi posisi sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm |

| X / Z sumbu kaulangan | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | |

| Pindah Tailstock | spésifikasi leungeun baju Tailstock | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 |

| perjalanan Tailstock | 40-460mm | 50-600mm | 0-790mm | ф150/200mm | ф150/200mm | |

| Rentang tekanan tailstock | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | |

| Métode gerak Tailstock | Programmable hidrolik | Programmable hidrolik | Didorong sadel, | (Hardway) Hidrolik disetir | ||

| Spindle | Spindle taper | A2-5 | A2-6 | A2-6 | A2-8 | A2-8 |

| Diaméter spindle bore | f56 mm | ф66 mm | ф66 mm | f88 mm | f88 mm | |

| Max. Laju spindle | 6000 rpm | 4500 rpm | 4500 rpm | 2500 rpm | 2500 rpm | |

| kakuatan motor Spindle | 7,5 / 11KW | 11KW | 11/15KW | 15KW | 15KW | |

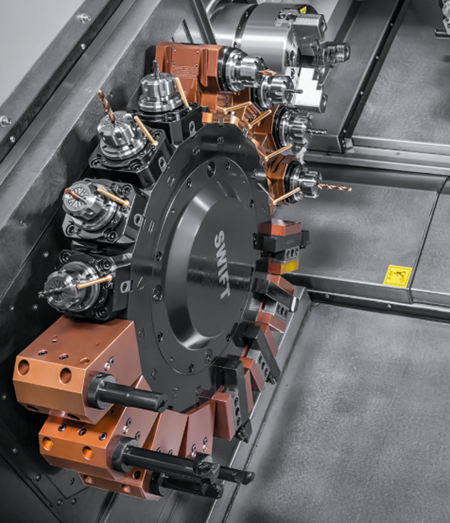

| Servo Powered turret | BMT40/12 Stasion | BMT55/12 Stasion | BMT55/12 Stasion | BMT65/12 Stasion | BMT65/12 Stasion | |

| Turret | Ukuran disc alat | 240 | 330 | 330 | 380 | 380 (rel teuas) |

| spésifikasi wadah alat | □20×20 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Panyekel alat boring | ф25 mm | ф32 mm | ф32 mm | ф40 mm | ф40 mm | |

| 0 derajat sirah panggilingan samping (1 stasiun) | ER20 / 3000rpm | ER32 / 3000rpm | ER32 / 3000rpm | ER40 / 3000rpm | ER40 / 3000rpm | |

| 90 derajat sirah panggilingan samping (1 stasiun) | ER20 / 3000rpm | ER32 / 3000rpm | ER32 / 3000rpm | ER40 / 3000rpm | ER40 / 3000rpm | |

| Lain | Total kapasitansi | 22KW | 26KW | 26KW | 34KW | 34KW |

| Alat mesin beurat net | Ngeunaan 3800Kg | Ngeunaan 4000Kg | Kira-kira 5000Kg | Ngeunaan 7000Kg | Ngeunaan 7800Kg | |

| Ukuran mesin (panjang × lebar × jangkungna) | 2600 × 1700 × 1950 | 2800 × 1700 × 2000 | 2900 × 2000 × 2200 | 6000 × 2300 × 2550 | 6500 × 2300 × 2550 | |

| Proyék | CNC-860TMC(2000) | CNC-860TMC(3000) | CNC-960TMC(1000) | CNC-960TMC(1500) | CNC-960TMC(2000) | CNC-960TMC(3000) | |

| Ranjang Ranjang | Ranjang sareng dasarna didamel tina beusi tuang kualitas luhur, sareng ranjangna condong 45 °. | Ranjang sareng dasarna didamel tina beusi tuang anu kualitas luhur, sareng ranjangna miring dina 45 °. | |||||

| Ngolah Range | Max. diaméterna ayun leuwih ranjang | 780 mm | 780 mm | 880 mm | 880 mm | 880 mm | 880 mm |

| Max. diaméterna ngolah cakram | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | |

| Max. ngolah diaméter gerbong | 500 mm | 500 mm | 600 mm | 600 mm | 600 mm | 600 mm | |

| Max. ngolah panjang bar | 1900 mm | 2900 mm | 900 mm | 1400 mm | 1900 mm | 2900 mm | |

| Max. diaméterna bar | ф75 mm | ф75 mm | ф91 mm | ф91 mm | ф91 mm | ф91 mm | |

| Travel Feed | Max. perjalanan sumbu X | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm |

| Max. perjalanan Z-sumbu | 2050 mm | 3050 mm | 1050 mm | 1550 mm | 2050 mm | 3050 mm | |

| Max. perjalanan sumbu Y | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | |

| X / Z / Y sumbu speed gancang | 16m/min | 16m/min | 16m/min | 16m/min | 16m/min | 16m/min | |

| X / Z / Y screw diaméterna / pitch | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | |

| X / Z lebar pituduh linier | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | |

| Motor servo sumbu X | β22 (Rem) | β22 (Rem) | β22 (Rem) | β22 (Rem) | α22(Rem) | α22(Rem) | |

| Z-sumbu servo motor | β22 | β22 | β12 (Rem) | β12 (Rem) | α12(Rem) | α12(Rem) | |

| Y-sumbu servo motor | β22 | β22 | β22 | β22 | β22 | β22 | |

| Servo turret motor | 1KW | 1KW | 1KW | 1KW | 1KW | 1KW | |

| Motor sirah kakuatan | β22 | β22 | β22 | β22 | β22 | β22 | |

| Akurasi | Akurasi posisi sumbu X/Z | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm |

| X / Z sumbu kaulangan | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | ± 0,003/300mm | |

| Pindah Tailstock | spésifikasi leungeun baju Tailstock | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 | Mohs #5 |

| perjalanan Tailstock | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | ф150/200mm | |

| Rentang tekanan tailstock | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | 5-30Kg/cm² | |

| Métode gerak Tailstock | (Hardway) Didorong hidrolik | (Hardway) Didorong hidrolik | |||||

| Spindle | Spindle taper | A2-8 | A2-8 | A2-11 | A2-11 | A2-11 | A2-11 |

| Diaméter spindle bore | f88 mm | f88 mm | ф105 mm | ф105 mm | ф105 mm | ф105 mm | |

| Max. Laju spindle | 2500 rpm | 2500 rpm | 2200 rpm | 2200 rpm | 2200 rpm | 2200 rpm | |

| kakuatan motor Spindle | 22KW | 30KW | 15KW | 15KW | 22KW | 30KW | |

| Servo Powered turret | BMT65/12 Stasion | BMT65/12 Stasion | BMT65 / 12Stasiun | BMT65/12 Stasion | BMT65/12 Stasion | BMT65/12 Stasion | |

| Turret | Ukuran disc alat | 380 (rel teuas) | 380 (rel teuas) | 380 (rel teuas) | 380 (rel teuas) | 380 (rel teuas) | 380 (rel teuas) |

| spésifikasi wadah alat | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Panyekel alat boring | ф40 mm | ф40 mm | ф40 mm | ф40 mm | ф40 mm | ф40 mm | |

| 0 derajat sirah panggilingan samping (1 stasiun) | ER40 / 4000rpm | ER40 / 4000rpm | ER40 / 3000rpm | ER40 / 3000rpm | ER40 / 4000rpm | ER40 / 4000rpm | |

| 90 derajat sirah panggilingan samping (1 stasiun) | ER40 / 4000rpm | ER40 / 4000rpm | ER40 / 3000rpm | ER40 / 3000rpm | ER40 / 4000rpm | ER40 / 4000rpm | |

| Lain | Total kapasitansi | 48KW | 55KW | 34KW | 34KW | 48KW | 55KW |

| Alat mesin beurat net | Ngeunaan 9000Kg | Ngeunaan 11500Kg | Ngeunaan 7000Kg | Ngeunaan 7800Kg | Ngeunaan 9000Kg | Ngeunaan 11500Kg | |

| Ukuran mesin (panjang × lebar × jangkungna) | 7000 × 2300 × 2550 | 8500 × 2300 × 2550 | 6000 × 2300 × 2550 | 6500 × 2300 × 2550 | 7000 × 2300 × 2550 | 8500 × 2300 × 2550 | |

Fitur Konfigurasi

Spindle

Ngarojong-precision tinggi jeung beurat-tugas motong pikeun ngaronjatkeun produktivitas.

Turret

Ningkatkeun reliabiliti indexing sarta ensures rigidity tinggi.

Sistim

Standar FANUC F Oi-TF Ditambah Sistim CNC, kinerja processing tinggi laju operasi tinggi, betah tinggi pamakéan.

Rigidity tinggi

Beurat-tugas matakIron Base Jeung komponén, Nyerep shock kuat jeung stabilitas tinggi.

Bal screw

Pretensioning screw, backlash jeung elongation naékna suhu dileungitkeun sateuacanna.

Roller Linear Guide

Motong arc, motong bevel, sareng tékstur permukaan seragam. rotasi-speed tinggi universal.