-speed tinggi Horizontal Machining Center CW Series

Konpigurasikeun

Fitur

Struktur kaku anu luhur ngamungkinkeun pamrosésan precision tinggi

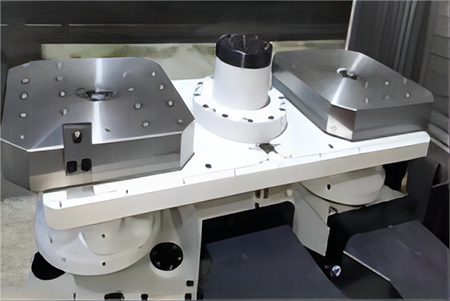

Gandeng of worktable: Sambungan antara awak worktable jeung Usuk ieu tightened ku congcot 4-titik kalawan gaya clamping palet of 73.2KN. The gandeng tina tabel indexing ngagunakeun gaya clamping worktable of 85.2KN pikeun ngajaga processing stabil tina motong beurat.

Desain miring sumbu X: Jangkungna pesawat pamasangan anu béda tina pituduh linier sumbu X mastikeun kaku anu luhur sareng ngahontal posisi anu gancang sareng presisi luhur.

Desain processing-precision tinggi

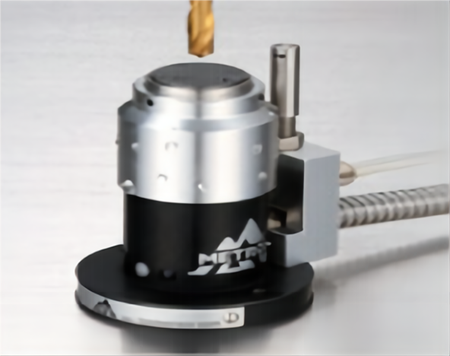

Diwangun-di spindle / spindle listrik: The diwangun-di spindle / spindle motorized nyata ngurangan Geter salila operasi-speed tinggi, ngahontal finish permukaan alus teuing, sahingga nyata manjangkeun umur alat.

Kontrol suhu spindle

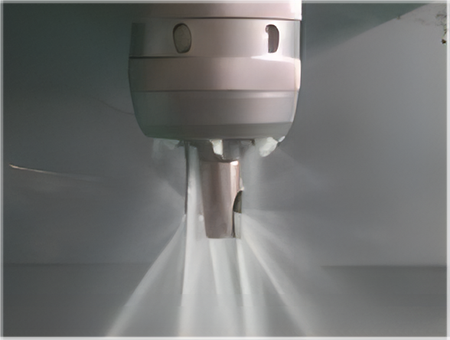

Pikeun ngahontal machining-precision tinggi, coolant ieu medar ngaliwatan bantalan spindle jeung kotak spindle pikeun ngurangan parobahan termal dina spindle nu.

Skrup bola sumbu X, Y, Z kalayan penyejukan kerung: Coolant, anu dikontrol ku suhu ku unit penyejukan, ngiderkeun sumbu sekrup bola, ku kituna mastikeun akurasi pamrosésan anu stabil dina operasi berkecepatan tinggi.

Panutup panyalindungan sumbu X, Y: Penjaga lembaran logam multi-bagian sareng sikat diganti ku hansip lipat gaya akordion. Desain kompak ieu sacara efektif ngadalikeun chip sareng motong cairan di daérah mesin.

Spésifikasi teknis

| Barang | Unit | CW4000 | CW5000 | CW6800 | CW8800 | |

| Méja gawé | Méja Gawé (L×W) | mm | 400 × 400 | 500 × 500 | 630 × 630 | 800 × 800 |

|

| Jumlahworktable | pcs | 2 | 2 | 2 | 2 |

|

| Max.Beban worktable | kg | 300 | 500 | 1200 | 2000 |

|

| Max.ukuran workpiece of worktable | mm | 0710*510 | 0800*1000 | 01100*1000 | 01450*1200 |

|

| Jangkungna worktable tina taneuh | mm | 1054 | 1165 | 1380 | 1400 |

|

| nilai division minimum | ° | 0.001 | 0.001 | 0.001 | 0.001 |

| Eupan | X / Y / Z sumbu gerakan gancang | m / mnt | 60/60/60 | 60/60/60 | 60/60/60 | 60/60/60 |

|

| Motong laju eupan | m / mnt | 1-10 | 1-10 | 1-10 | 1-10 |

| Lalampahan | X / Y / Z perjalanan sumbu | mm | 500×450×400 | 800×800×800 | 1100 × 900 × 980 | 1500 × 1200 × 1325 |

|

| Jarak ti puseur spindle ka worktable | mm | 130-580 | 130-930 | 150-1050 | 100-1300 |

| Spindle | Jarak ti tungtung spindle ka puseur worktable | mm | 125-525 | 50-850 | 150-1130 | 100-1425 |

|

| Spésifikasi spindle (diaméter pamasangan / modeu transmisi) | mm | 170 / Diwangun-di | 250 / Diwangun-di | 300 / Diwangun-di | 300 / Diwangun-di |

|

| liang taper Spindle | mm | BT40 | BT40 | BT50 | BT50 |

|

| Max.spinselspipis | r / mnt | 15000 | 15000 | 8000 | 8000 |

|

| Spindlemotorpower | kW | 11/15 | 15/18.5 | 18.5/30 | 18.5/30 |

|

| Spindlemotortorque | Nm | 32/53.4 | 95.5/250 | 305/623 | 305/623 |

| Parabot | Alatmagazinecapacity | T | 23 | 50 | 40 | 40 |

|

| Max.tooldukuranana/length | mm | 110/250 | 150/500 | 250/500 | 250/500 |

|

| Max.toolwdalapan | kg | 8 | 8 | 20 | 25 |

| Tilu sumbu | sumbu Xguihrail (Lebar rel / Jumlah Slider) | mm | 35/2 | 45/2 | 55/2 | 55/6 |

|

| sumbu Yguihrail (Lebar rel / Jumlah Slider) |

| 35/2 | 35/2 | 55/2 | 55/2 |

|

| sumbu Zguihrail (Lebar rel / Jumlah Slider) |

| 35/2 | 45/2 | 55/4 | 65/4 |

|

| screw sumbu X | / | 2R40×20 | 2R40×20 | 2R50×20 | 2R50×20 |

|

| screw sumbu Y | / | 2R40×20 | 2R40×20 | 2R50×20 | 2R50×20 |

|

| screw sumbu-Z | / | 2R36×20 | 2R40×20 | 2R50×20 | 2R50×20 |

| Akurasi | Positioningakatepatan | mm | ± 0,005/300 | |||

|

| diulang-ulangpositioningakatepatan | mm | ± 0,003/300 | |||

| Lain | Sarat hawa | kg/cm² | ≥6 | |||

|

| Aliran gas | L/min | ≥200 | |||

|

| Mesinwdalapan (komprehensif) | T | 6 | 11.2 | 20 | 30 |

|

| Ukuran mesin (L × W × H) | mm | 1680*5510*2870 | 2785*5845*3040 | 3300*6798*3400 | 4230 × 8447 × 3440 |

Konfigurasi Bubuka

meja kerja bursa ganda

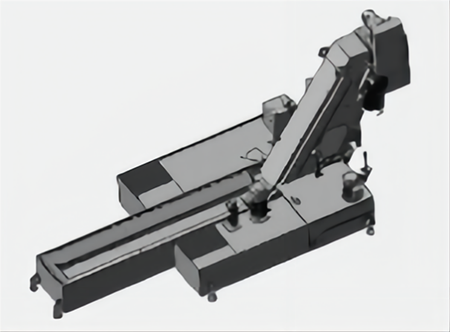

Panto otomatis hareup

Stasion hidrolik

Alat setter

(Sistem deteksi karusakan alat)

Ranté chip conveyor

Spindle CTS

(Tekanan CTS 15Bar)

Ngolah Kasus

Mesin Konstruksi, Industri Aerospace, Industri Otomotif

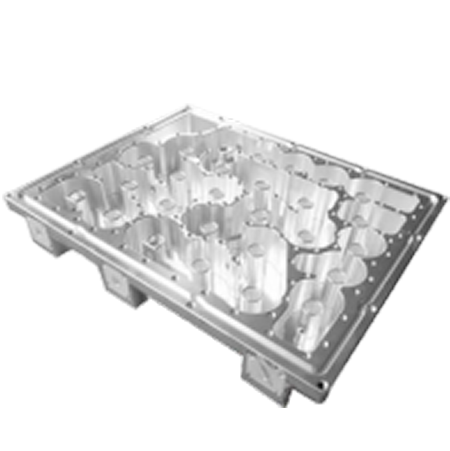

Perumahan batré énergi anyar

Lempeng alur

Bantalan transmisi

Splitter Shell

Rongga komunikasi

Perumahan kopling

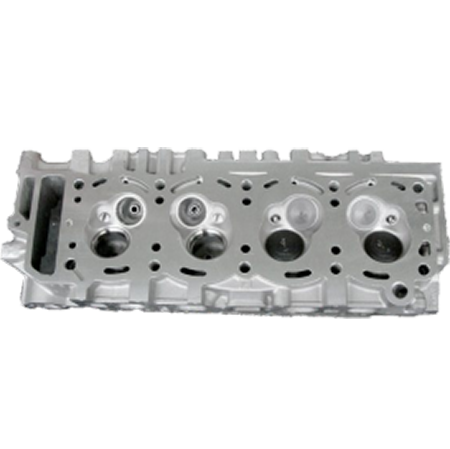

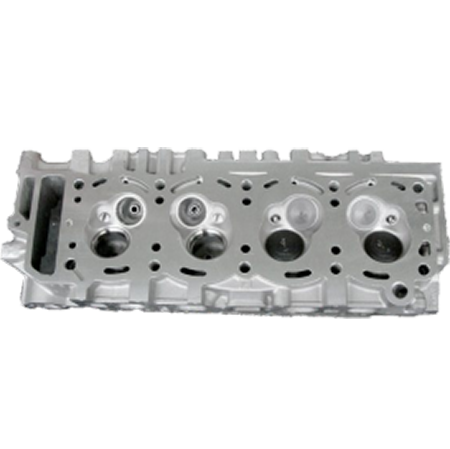

sirah silinder

sirah silinder